Logistics modeling is an indispensable tool for successfully managing and organizing any business’ supply chain. From tracking goods and performance indicators to optimizing operations and anticipating future needs, logistic modeling provides businesses of all sizes with control over their transportation activities.

In this guide, we’ll look at the fundamentals, and how it can give your organization an edge.

What is Logistics Modeling?

Logistics modeling is the use of computer systems to simulate various scenarios related to goods movement and transportation management.

With these simulations, companies gain better insight into their supply chain operations, uncover hidden optimization opportunities, identify cost-saving or efficiency opportunities, and anticipate future trends and changes.

Through advanced analytics and data-driven decision making techniques, you can make more informed decisions based on accurate information, instead of guesswork or assumptions.

Benefits of Logistics Modeling

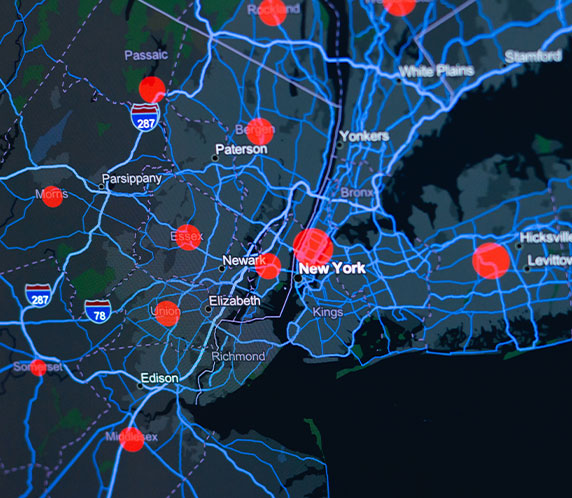

- Optimizing Route Optimization: By understanding the parameters associated with freight movement (i.e., origin/destination locations, cargo weight/size/type), companies can create models that optimize routes for maximum efficiency, while taking into account constraints like limited capacity or timelines.

- Reduced Operating Costs: Businesses that accurately forecast future needs can take proactive measures to keep costs low by ensuring they always have enough qualified resources for the job, without overspending unnecessary supplies or services.

- Enhancing Delivery Accuracy: Through advanced route planning and scheduling capabilities provided by a logistics model, businesses can guarantee deliveries arrive on time, so customers remain satisfied with service levels.

- Enhanced Visibility Across the Supply Chain: By integrating real-time data from various sources, like GPS tracking devices on trucks or other modes of transport, into their logistics model, companies gain access to up-to-date information about shipments so they know precisely where goods are at any given time. This insight allows them to make better decisions when faced with delays or other unforeseen circumstances during transit.

How Can I Begin With Logistics Modeling?

Getting started doesn’t have to be complex or expensive! Today, there are numerous tools on the market that provide straightforward setups and user interfaces, so you can get up and running quickly without needing special IT skill sets or costly hardware purchases.

Look for solutions tailored specifically towards your industry (e.g., automotive parts manufacturers versus retail shipping), so that you get the most out of your investment in terms of cost savings and improved visibility across operations.

Once you identify which tool best meets your company’s needs, start creating customized models based on past performance data, to generate predictive models that can guide future decisions regarding transportation management and goods movement activities within your supply chain network!

Logistics modeling is an invaluable asset for businesses seeking to gain an edge in an increasingly competitive global marketplace by streamlining their transportation processes and cutting down costs associated with inefficient goods movements along their supply chains. Whether you’re just starting out or looking to enhance existing processes within your operation, understanding what features you require before investing in software tools is a must.

Not sure which software is best for your company? Contact us today. We’d be happy to help!

Frequently Asked Questions:

What are the advantages of logistics modeling?

It can help optimize operations and identify potential inefficiencies, leading to cost reductions and improved performance.

What types of logistics models exist?

Different logistics models exist, such as network design models, transportation models, inventory models and demand forecasting models.

What factors are taken into account when creating logistics models?

It takes into account factors like transportation costs, inventory costs, warehousing expenses, lead times and order processing times, as well as customer demand.

What methods are employed in logistics modeling?

Popular methods include linear programming, simulation, queuing theory and discrete event simulation.

What role does technology play in logistics modeling?

Technology plays a pivotal role by providing data collection, analysis, and visualization – essential steps for creating accurate and efficient logistics models.

What industries can benefit from logistics modeling?

Industries such as manufacturing, retail, healthcare and transportation can greatly benefit from logistics modeling.

How Can Logistics Modeling Aid Supply Chain Management?

It can help optimize supply chains, decrease lead times, improve inventory management and raise customer service levels.

Who typically performs logistics modeling?

Operations research analysts, management consultants, and logistics specialists.

What are the challenges inherent to logistic modeling?

Logistics modeling presents many challenges, such as data accuracy and availability, model complexity, shifting business conditions and the requirement for specialized skills.

Not sure which logistics models are best for your company? Contact us today. We’d be happy to help!